Executive Summary

The semiconductor supply chain is among the most complex and globally interdependent production systems ever built by humanity. It spans continents, links dozens of specialized industries, and supports trillions of dollars in downstream economic activity. Yet, this very interdependence also makes it vulnerable to geopolitical tension, natural disasters, and technological chokepoints.

This article examines the semiconductor supply chain from end to end: design, fabrication, equipment, materials, assembly and testing, and final integration into devices. It explores key challenges—such as geographic concentration, export controls, talent shortages, and environmental sustainability—and assesses the ongoing transformation driven by new technologies, policies, and strategic realignments.

I. Anatomy of the Semiconductor Supply Chain

The semiconductor industry can be visualized as a highly stratified ecosystem with each layer dependent on the others. To understand its vulnerabilities and opportunities, one must first break down this ecosystem into its primary segments.

1. Design and Intellectual Property (IP)

The process begins with chip design. Fabless companies such as Qualcomm, Nvidia, AMD, and Apple focus exclusively on creating blueprints for integrated circuits. These designs often rely on sophisticated tools provided by a handful of Electronic Design Automation (EDA) firms—Synopsys, Cadence, and Siemens EDA—dominating a market with a few dozen essential tools.

The concentration of EDA technology, primarily in the United States, makes it a key strategic leverage point in global semiconductor competition.

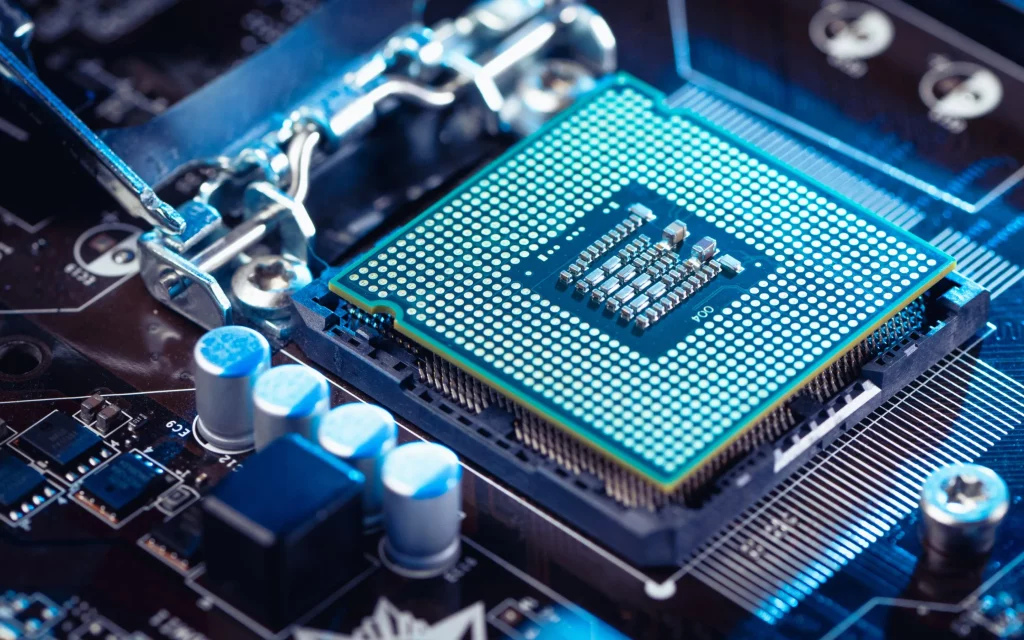

2. Fabrication (Front-End Manufacturing)

The fabrication process transforms silicon wafers into chips by layering, etching, doping, and patterning billions of transistors. This step is capital-intensive and technologically demanding.

Key players:

- TSMC (Taiwan)

- Samsung Electronics (South Korea)

- Intel (U.S.)

- SMIC (China) – still behind in leading-edge nodes.

Advanced fabrication nodes—measured in nanometers (nm)—currently down to 3nm and soon 2nm—require Extreme Ultraviolet (EUV) lithography, supplied almost entirely by ASML (Netherlands). Without ASML’s machines, no company can mass-produce the most advanced chips.

3. Equipment Suppliers

Fabrication would be impossible without highly specialized tools for lithography, deposition, etching, metrology, and cleaning.

Critical players:

- ASML (Netherlands) – EUV lithography

- Applied Materials, Lam Research, KLA (U.S.) – etching, deposition, and inspection

- Tokyo Electron (Japan) – wafer processing

- Screen Semiconductor (Japan) – cleaning systems.

These firms form the technological backbone of chip production and often define the frontier of manufacturing capability.

4. Materials and Chemicals

High-purity silicon wafers, photoresists, gases, and specialty chemicals are the raw materials of chips. Japan remains a dominant supplier of many advanced materials—such as photoresists and fluorinated polyimides—highlighting yet another point of geographic concentration.

5. Assembly, Testing, and Packaging (Back-End)

After fabrication, chips must be sliced, tested, and packaged before they can be integrated into final devices.

Key players:

- ASE Group (Taiwan)

- Amkor Technology (U.S./Korea)

- JCET (China)

While traditionally considered less high-tech, advanced packaging—such as 3D stacking and chiplets—has become increasingly important in sustaining performance gains as Moore’s Law slows.

II. Global Interdependence and Geographic Concentration

The semiconductor supply chain is a masterpiece of globalization: design often occurs in the U.S., software tools come from the U.S. and Europe, manufacturing in East Asia, equipment from Europe, Japan, and the U.S., and assembly and testing across Asia.

Yet, this interconnectedness also creates points of vulnerability.

- Taiwan’s Dominance: Produces over 90% of the world’s most advanced chips (≤7nm).

- South Korea’s Memory Leadership: Samsung and SK Hynix dominate DRAM and NAND markets.

- U.S. Strength in IP and EDA: Essential for design innovation.

- Japan’s Control of Materials: Critical suppliers of photoresists, high-purity gases, and wafers.

Any disruption in one link—whether due to natural disasters (e.g., 2011 Tōhoku earthquake affecting Japanese suppliers), political tensions, or pandemics—can reverberate through the global economy.

III. Challenges Confronting the Semiconductor Supply Chain

1. Geopolitical Tensions and Techno-Nationalism

The U.S.–China rivalry has transformed semiconductors into a battleground for technological supremacy. Export controls on advanced lithography machines and high-end GPUs aim to curb China’s progress in cutting-edge chips.

Beijing, in turn, is accelerating domestic capacity-building through subsidies, state-backed funds, and talent recruitment programs. The result is a gradual bifurcation of the semiconductor ecosystem—raising costs and undermining the efficiency gains achieved through decades of globalization.

2. Supply Chain Fragility and Pandemic Lessons

The COVID-19 pandemic exposed the risks of just-in-time manufacturing and extreme geographic concentration. Automakers and electronics companies faced severe shortages when a handful of fabs could not meet surging demand.

This experience has prompted companies and governments to rethink inventory strategies, diversify suppliers, and invest in more resilient supply networks.

3. Capital Intensity and Barriers to Entry

Building an advanced fab costs upwards of $20–25 billion, while keeping it at the cutting edge requires annual capital expenditures in the billions. This enormous financial hurdle has effectively limited leading-edge production to a few companies, raising concerns about over-dependence on a small set of players.

4. Talent Shortage

Semiconductor manufacturing demands highly skilled engineers and technicians. As fabs become more automated and complex, the talent gap is widening, especially in countries trying to rebuild domestic manufacturing capacity.

Efforts to address this include workforce development initiatives in the U.S., Europe, and Asia, but progress remains slow relative to industry needs.

5. Environmental Sustainability

Chip fabrication is energy-intensive and consumes vast amounts of ultrapure water and specialty chemicals.

- A single advanced fab can use 20 million liters of water per day.

- Growing concerns about carbon emissions and waste disposal have made environmental sustainability a critical aspect of long-term supply chain resilience.

IV. The Transformation Underway

1. Policy Interventions: The New Industrial Age

Governments are now playing a more active role in shaping semiconductor supply chains:

- United States: The CHIPS and Science Act (2022) allocates over $52 billion in subsidies and R&D funding to boost domestic manufacturing.

- European Union: The EU Chips Act aims to double Europe’s share of global chip production to 20% by 2030.

- Japan and South Korea: Offering tax breaks and subsidies to attract fabs from TSMC, Micron, and other players.

- China: Continuing heavy investment despite export restrictions.

This new wave of industrial policy marks a departure from the laissez-faire globalization era that dominated the late 20th century.

2. Technological Shifts in Manufacturing

Several transformative trends are reshaping the supply chain:

- Chiplet Architectures: Breaking chips into modular components reduces design complexity and enhances flexibility.

- Advanced Packaging and 3D Stacking: Increasing performance without further shrinking transistor nodes.

- Automation and Smart Manufacturing: AI-driven process control improves yields and reduces costs.

- Green Manufacturing Practices: Driven by regulatory and corporate sustainability goals.

3. The Push for Geographic Diversification

Companies are seeking to reduce over-reliance on Taiwan and South Korea by building fabs in the U.S., Europe, and Southeast Asia. While diversification can improve resilience, it also raises costs due to less efficient clustering and higher labor expenses.

V. Case Studies of Resilience and Vulnerability

Case 1: TSMC – The King of Advanced Nodes

TSMC’s unmatched expertise in leading-edge manufacturing has made it indispensable to the global tech ecosystem. However, its geographic concentration in Taiwan exposes it to geopolitical risks.

Case 2: ASML – A Critical Chokepoint

ASML’s EUV lithography machines—each costing over $150 million—represent the pinnacle of photonics and engineering. Without them, no country can mass-produce 5nm or smaller chips. Export controls restricting access to these tools highlight the fragility of global supply interdependence.

Case 3: Samsung and Memory Resilience

Samsung’s global footprint in Korea, the U.S., and elsewhere has helped it maintain more diversified manufacturing, though it remains exposed to regional geopolitical tensions.

Case 4: The Automotive Shortage of 2021

The global automotive industry’s crisis during the pandemic demonstrated how shortages in relatively low-tech “legacy nodes” (28nm and above) can disrupt entire sectors, emphasizing that supply chain resilience requires attention beyond just advanced chips.

VI. Building a More Resilient and Sustainable Future

A resilient semiconductor supply chain must be:

- Diversified geographically and technologically.

- Collaborative across national boundaries to leverage strengths while managing security concerns.

- Sustainable in environmental impact to ensure long-term viability.

- Inclusive of Workforce Development to address talent shortages and keep pace with technological change.

Global alliances—such as the U.S.–Japan–Netherlands trilateral cooperation on equipment, and EU–U.S. dialogues on supply chain security—illustrate the potential for constructive collaboration even amid strategic competition.

Conclusion: Navigating Complexity in an Era of Fragmentation

The semiconductor supply chain is both a triumph of human cooperation and a source of strategic vulnerability. As nations race to secure their positions in this critical industry, the challenge lies in balancing national security concerns with the need for global collaboration.

In the coming decade, the shape of the semiconductor ecosystem will be determined not only by technological innovation but also by political choices. Whether the world moves toward greater resilience and cooperation or toward costly fragmentation will have profound implications for the global economy, innovation, and even geopolitical stability.